Resumen: Los efluentes vertidos por los sistemas de recirculación de acuicultura (SRA) son ricos en nutrientes como el nitrógeno y el fósforo. Si no se gestionan adecuadamente, se convierten en contaminantes y su tratamiento para cumplir las normas de vertido suele ser costoso. Un proyecto reciente del Instituto Nofima de Noruega ha transformado este efluente en un recurso valioso, utilizándolo con éxito para cultivar el alga roja comestible Palmaria palmata (Dulse). Se trata de un enfoque novedoso para que los SAR logren un "reciclado interno" y un valor añadido.

Aspectos destacados de la investigación: Los científicos utilizaron el efluente de un RAS de salmón en tierra para probar sus efectos sobre el crecimiento de algas rojas en diferentes concentraciones. Los resultados revelaron que una mezcla 50% de efluente de RAS y agua de mar ofrecía las condiciones de crecimiento óptimas para las algas rojas, al tiempo que lograba la mayor eficiencia de eliminación de amonio y nitrato. Este hallazgo identifica el equilibrio ideal entre el suministro de nutrientes procedentes de las aguas residuales de la acuicultura y la tolerancia de crecimiento de las algas.

Doble valor: Económico y Ecológico

Borrar relación entrada-salida: El estudio indica que, en condiciones experimentales, pueden producirse aproximadamente 257 gramos de algas rojas frescas por cada kilogramo de alimento para peces consumido. Esto proporciona una base directa para escalar un sistema complementario de producción de algas.

Producto de alto valor: La palmaria palmata es muy apreciada en Europa como superalimento, consumido directamente en ensaladas o como condimento. Su precio de mercado es significativamente superior al de los ingredientes convencionales de los piensos acuícolas.

Beneficio medioambiental en bucle cerrado: Las algas absorben nutrientes, reduciendo directamente la carga de tratamiento y el coste asociado al efluente. Además, su proceso de crecimiento secuestra dióxido de carbono, reduciendo así la huella de carbono global del sistema de acuicultura.

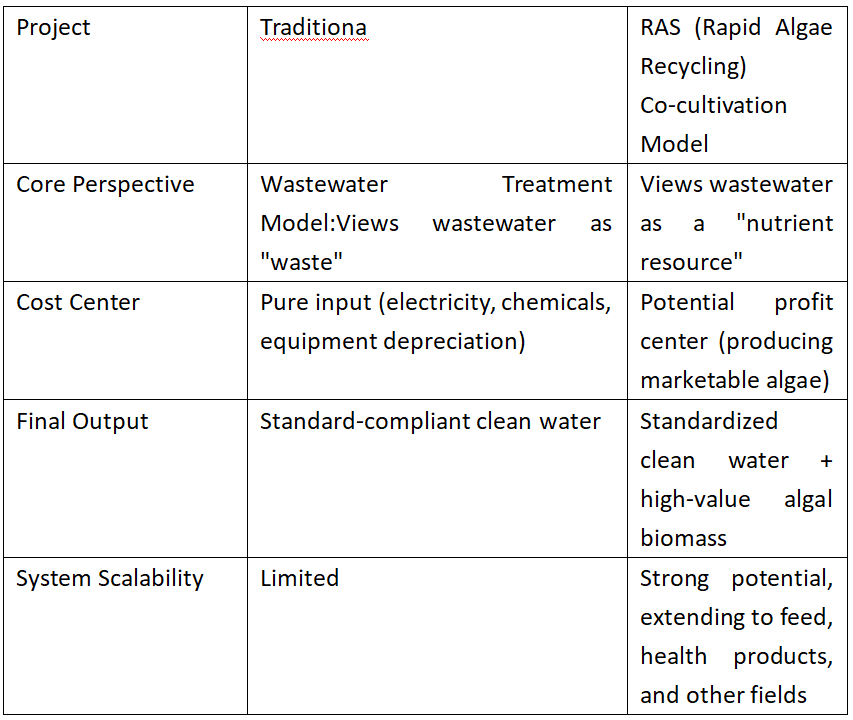

Comparación de modelos: Tratamiento tradicional frente a utilización de recursos

Perspectivas del sector: Los investigadores noruegos señalan que, basándose únicamente en el consumo anual de 100.000 toneladas de pienso de la industria noruega del salmón de tierra, los nutrientes presentes en sus efluentes podrían sustentar una importante industria de algas. Esto pone de manifiesto un importante potencial: Las instalaciones de SAR podrían transformarse en "centros de producción combinada de proteínas y plantas de alto valor".

Puntos clave de aplicación para las explotaciones agrícolas:

Análisis de viabilidad: Inicialmente, compruebe el contenido de nutrientes específicos (por ejemplo, los niveles de nitrógeno y fósforo) de su propio efluente de SRA para evaluar su idoneidad para el cultivo de las especies de algas objetivo.

Selección del proceso: Considere las tecnologías de biorreactores a las que se hace referencia en la investigación, como el "cultivo continuo" o el "cultivo por perfusión", en función del presupuesto de inversión y del nivel de automatización deseado.

Primero el mercado: Antes de invertir en la tecnología, hay que investigar la aceptación de las algas comestibles en el mercado local o de destino e identificar los posibles canales de venta para garantizar la viabilidad económica del proyecto.