Durante mucho tiempo, la maricultura mundial ha operado principalmente en aguas costeras. Sin embargo, el cultivo intensivo y las prácticas insostenibles han provocado crecientes conflictos con otras actividades costeras como la navegación, el turismo y la conservación. Este espacio abarrotado suele provocar la degradación del medio ambiente, la fuga de peces y la propagación de enfermedades en las zonas cercanas a la costa.

Para hacer frente a estos retos, el sector está recurriendo a lugares más amplios y respetuosos con el medio ambiente: las profundidades marinas. La acuicultura en aguas profundas ofrece un vasto espacio oceánico, lo que reduce los conflictos con otros sectores marinos. También ofrece una calidad de agua superior y un intercambio de agua sostenible y natural, allanando el camino para una producción de marisco más sostenible.

Evolución de las tecnologías clave

Utilizar las condiciones de las profundidades marinas para la piscicultura se ha revelado como la opción óptima para garantizar un suministro estable de pescado de alta calidad. Pionera en países pesqueros como Noruega, Estados Unidos y Suecia, las principales direcciones tecnológicas son las redes a gran escala y las plataformas de acuicultura.

Con el apoyo de la tecnología moderna, estas naciones han avanzado rápidamente en la automatización de las grandes redes agrícolas. El desarrollo y la aplicación de la tecnología de la información han impulsado notablemente la eficiencia y mejorado el control de la gestión.

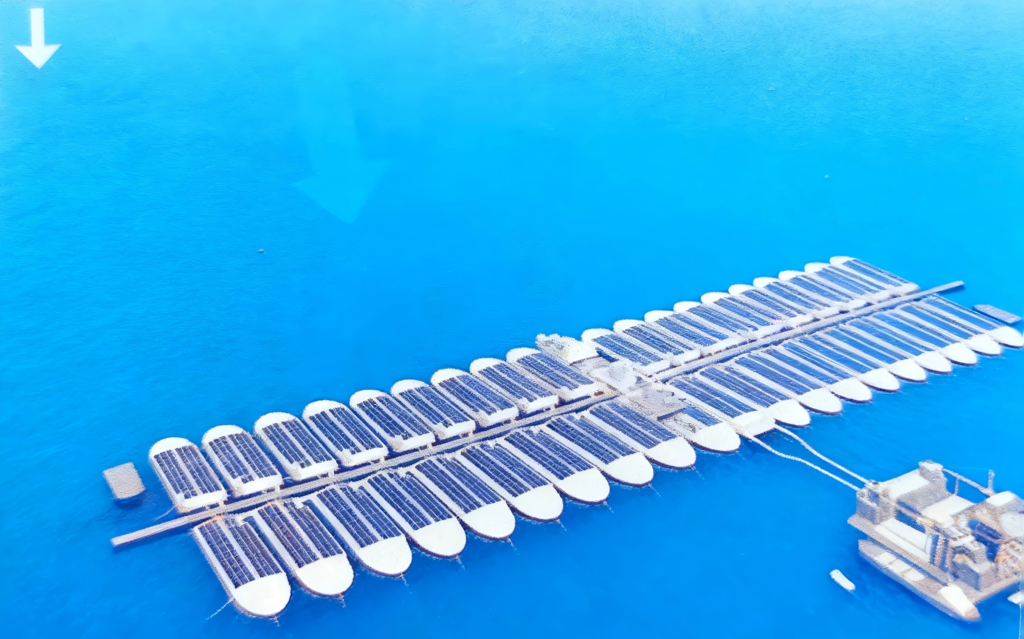

Proyectos como la plataforma europea "Offshore Large-Scale Net Pen Platform" integran diversas tecnologías (grandes redes, energía eólica marina, control remoto, cría de alevines de alta calidad, piensos ecológicos, alimentación automatizada y gestión sanitaria) para formar un sistema completo de ingeniería acuícola en alta mar.

Otra dirección de investigación clave es el uso de buques de acuicultura. Desde los años ochenta y noventa, los países pesqueros avanzados han venido desarrollando diversas plataformas, como estructuras flotantes, compartimentos de cría en buques y buques de red semisumergibles. Estas innovaciones han dado importantes resultados y han creado una sólida base tecnológica para el desarrollo a escala industrial.

Clasificación y diseño de los sistemas de acuicultura

En función de las condiciones actuales de cría en aguas profundas, los equipos pueden dividirse en dos categorías principales: Sistemas abiertos de corrales de red y sistemas cerrados de contención.

1. Sistemas Open Net Pen

Las jaulas de red abiertas se utilizan mucho en piscicultura marina. En Noruega, por ejemplo, los sistemas diseñados con una vida útil de 50 años se despliegan en aguas con alturas de ola significativas de 2-3 metros, clasificadas como "parcialmente expuestas."

Bolígrafos flexibles flotantes: A menudo fabricados con tubos de HDPE (polietileno de alta densidad) para su flotabilidad, estos corrales se ensamblan en armazones flotantes, combinados con redes y sistemas de amarre. Su gran elasticidad les permite resistir el oleaje, y suelen durar más de 10 años.

Bolígrafos rígidos flotantes: Se caracterizan por sus robustos bastidores, a menudo de acero, que ofrecen ventajas en cuanto a resistencia, estabilidad y flotabilidad. Proporcionan una plataforma estable para las operaciones y pueden integrar sistemas automatizados de alimentación y recolección. Pueden instalarse instalaciones de apoyo, como almacenes de piensos y grúas. Aunque pueden construirse en astilleros tradicionales, presentan inconvenientes como la necesidad de estructuras pesadas, una instalación costosa, vulnerabilidad en condiciones meteorológicas extremas y sistemas de amarre costosos.

Plumas flexibles semisumergibles: Su característica clave es la capacidad de sumergirse hasta cierta profundidad durante tormentas o tifones, minimizando los daños. Sin embargo, la necesidad de capacidad de inmersión aumenta la complejidad, la dificultad y el coste del diseño.

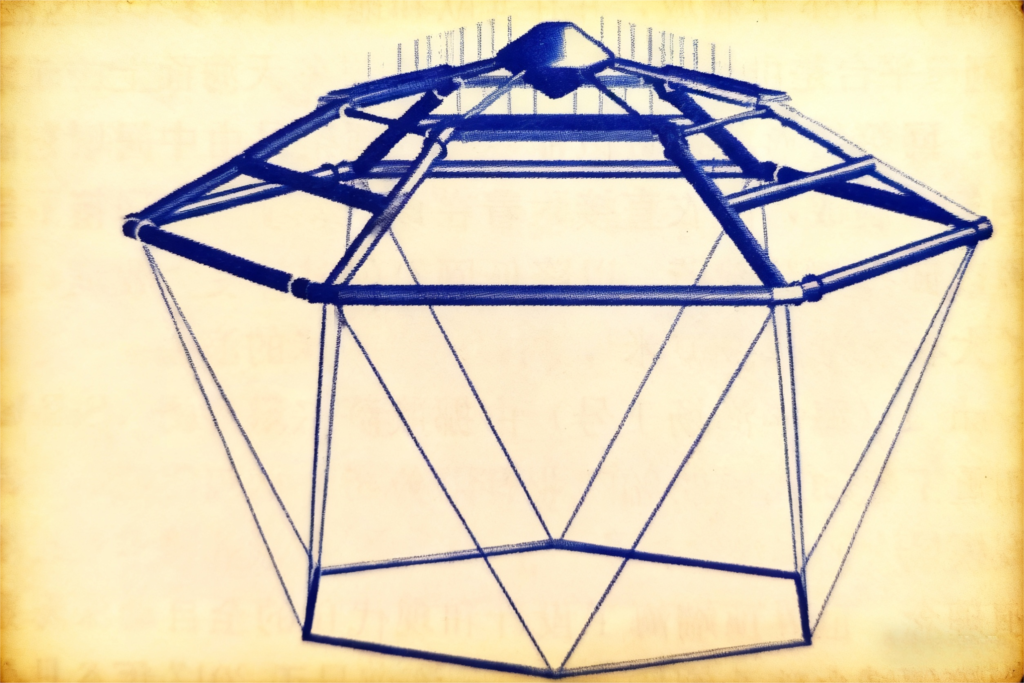

Plumas rígidas semisumergibles: Utilizan unidades de bastidor rígido, a menudo de acero, para evitar el movimiento y los cambios de volumen provocados por las olas y las corrientes. Equipados con tanques de lastre ajustables, pueden subirse o bajarse para evitar condiciones meteorológicas adversas. Este diseño también puede evitar la resonancia de las olas. Sumergirse durante los tifones aumenta la seguridad de la estructura y de los peces, pero los costes de construcción son elevados.

Bolígrafos totalmente sumergibles: Estos sistemas funcionan normalmente a una profundidad segura por debajo de la capa superficial peligrosa, pero pueden elevarse temporalmente para su mantenimiento o recolección. Se han desarrollado varios diseños, como Sadco, AquaPod y NSENGI, y algunos ya están en fase de pruebas exploratorias o de uso comercial.

2. Sistemas de contención cerrados

Introducidos en los años 90 para controlar mejor la calidad del agua y el proceso de producción, estos sistemas eran inicialmente terrestres con sistemas de recirculación del agua. Para proteger a los peces de cultivo de los piojos de mar y los parásitos, se desarrollaron sistemas cerrados flotantes para uso en aguas profundas.

Estos sistemas reponen continuamente el agua, ayudando a mantener los niveles adecuados de temperatura y oxígeno al tiempo que eliminan los residuos. Su principal ventaja es el intercambio controlado de agua, que permite una desinfección continua para mantener alejados a los patógenos. Los fenómenos externos, como la proliferación de algas, ya no afectan a los peces, y los residuos orgánicos se eliminan mediante biofiltros antes de verter el agua. También se eliminan las amenazas de los depredadores.

En comparación con las redes abiertas, estos sistemas ofrecen un mayor control, lo que permite optimizar los parámetros físicos para maximizar la productividad. Sin embargo, su despliegue en alta mar requiere una fuente de alimentación, que puede ser costosa si se transmite desde tierra. También implican elevados costes de construcción y equipamiento, requieren una gestión más intensiva para su supervisión y deben mitigar los efectos del chapoteo interno del agua sobre la estructura y los peces.