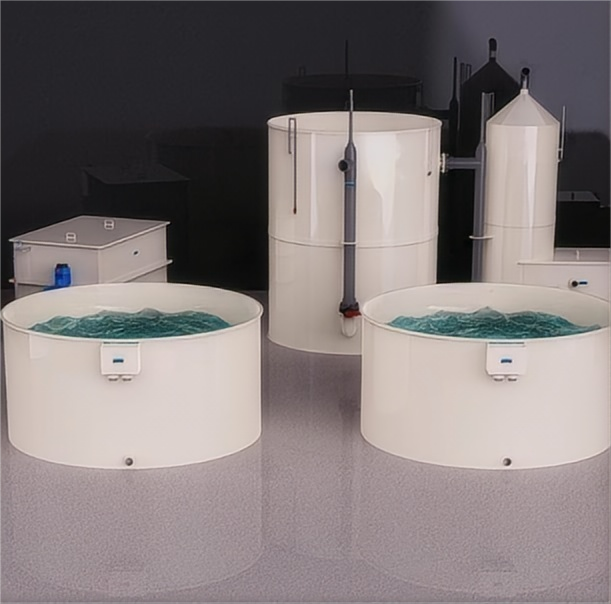

Abstract: What if there was a RAS farm that did not rely on imported feed, discharged no wastewater, used almost no medication, and offered full traceability? Would you consider this a vision of the future? Danish company Onnest has announced that it will begin construction of the world’s first such “fully circular” land-based fish farm between 2026 and 2027, with commercial-scale production of rainbow trout starting in 2028. This marks a significant leap for the RAS concept—from a “water-saving system” toward a “zero-waste ecosystem.”

Four Core Circular Designs

Feed Cycle: Microalgae are cultivated on-site as a core feed ingredient. The algae directly utilize nutrients released from processed fish waste and excess system heat for growth. This drastically reduces dependence on traditional imported ingredients like soy and fishmeal, lowering the carbon footprint from the source.

Water Cycle: The farm commits to “zero wastewater discharge.” All water is recirculated within a highly purified closed loop, with only evaporative losses being replenished. This completely eliminates potential impacts on the external aquatic environment.

Health Management Cycle: Through极致 automated control of dissolved oxygen, temperature, and water quality, an optimal environment is created. The target survival rate is set above 95%, with an ambition for “zero mortality.” This model plans to operate without the use of any vaccines or antibiotics, aiming to produce pure and safe premium products.

Information Traceability Cycle: Blockchain technology is introduced to record the entire lifecycle data for each fish—from fry, feed, and growing conditions to processing. Consumers can scan a code to access the complete farming history, achieving ultimate transparency and trust.

Implications for the Existing RAS Industry

Onnest’s blueprint is not unattainable; each individual technology already exists. Its breakthrough lies in the systemic integration of design and commercial courage. For existing RAS operations, this paradigm points toward a clear upgrade path:

Short-term: Strengthen data collection and traceability systems to enhance product storytelling and premium pricing potential.

Medium-term: Evaluate the possibility of introducing modular, on-site algae/insect feed production units to gradually reduce feed costs and supply risks.

Long-term: In new facility planning, embed “zero discharge” and “internalized resource cycles” as core design principles.

Challenges and Opportunities Coexist: This model requires a high initial investment and places extremely high demands on system stability and biological process control. However, it consequently enables the production of premium aquatic protein with a powerful brand narrative, meeting the highest environmental and animal welfare standards. Its target market is consumers willing to pay a premium for these values.